Agent Based Modeling

Under Construction

First Principle Based Four Dimensional Battery Degradation Model (4DM)

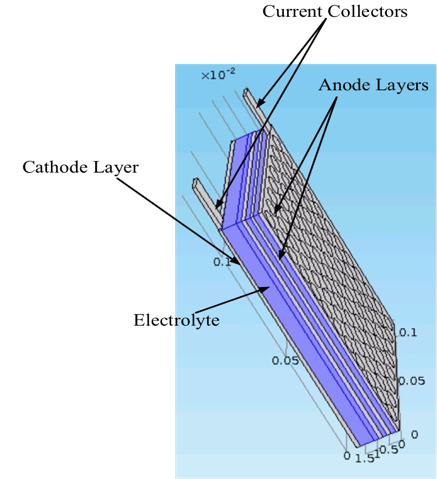

The First Principle Based Four Dimensional Battery Degradation Model (4DM) is computer simulation model for battery dynamics studies under different degradation and operating conditions. The 4DM is designed based on the physics of operation of the battery, i.e., the actual components such as anode, cathode, electrolyte, separator and current collector, are used to construct the model. This particular approach is used to bridge the gap between material science, electrochemical and electrical engineering.

The 4DM, because of the design, is capable of simulating:

- different battery chemistries,

- batteries of different capacities,

- progressive component degradation,

- different operating conditions – C-rates, temperatures, depth of discharge, partial charging and discharging effects,

- component degradation over time.

The 4DM provides a platform to study the sensitivity of the battery’s rate of change of voltage and capacity with respect to the degradation of different physical and electrochemical components. This feature/capability of the 4DM enables users to better understand the impact of different operating conditions on the degradation of their battery and determine appropriate use cases for their batteries to prolong the remaining useful life.

The 4DM has an intuitive user-interface that assists the user to perform different tests on the model under different operating conditions. The user interface is designed to be simple, yet intuitive and capable of providing the user with sufficient options to understand the working of the 4DM with access to the core back-end tool with all the features.

Sponsor:

Co-Estimation Algorithm

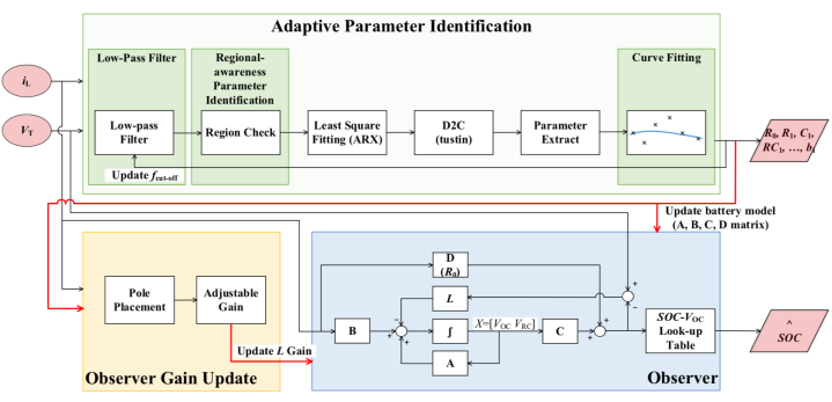

Real-time estimation of the state of charge (SOC) of the battery is a crucial need in the growing fields of plug-in hybrid electric vehicles and smart grid applications. The SOC estimation accuracy depends on the accuracy of the model used to describe the characteristics of the battery. To accurately estimate the SOC of the battery, a Co-Estimation algorithm is proposed. The Co-Estimation algorithm is developed based on a resistance–capacitance (RC)-equivalent circuit model to model the battery dynamics. Considering the parameters of the battery model are functions of the SOC, C-rate, temperature, and aging, the Co-Estimation algorithm adopts an adaptive online parameter-identification algorithm to identify and update the model’s parameters as they change. We also deployed a piecewise linearized mapping of the VOC–SOC curve along with continuously updating the parameters to accurately represent all of the battery’s static and dynamic characteristics. Using this adaptive structure, we design an observer based on the updating model to estimate the SOC as one of the states of the battery model.

Sponsor:

High Temperature Embedded/Integrated Sensors for Remote Monitoring of Reactor and Fuel Cycle Systems (HiTEIS)

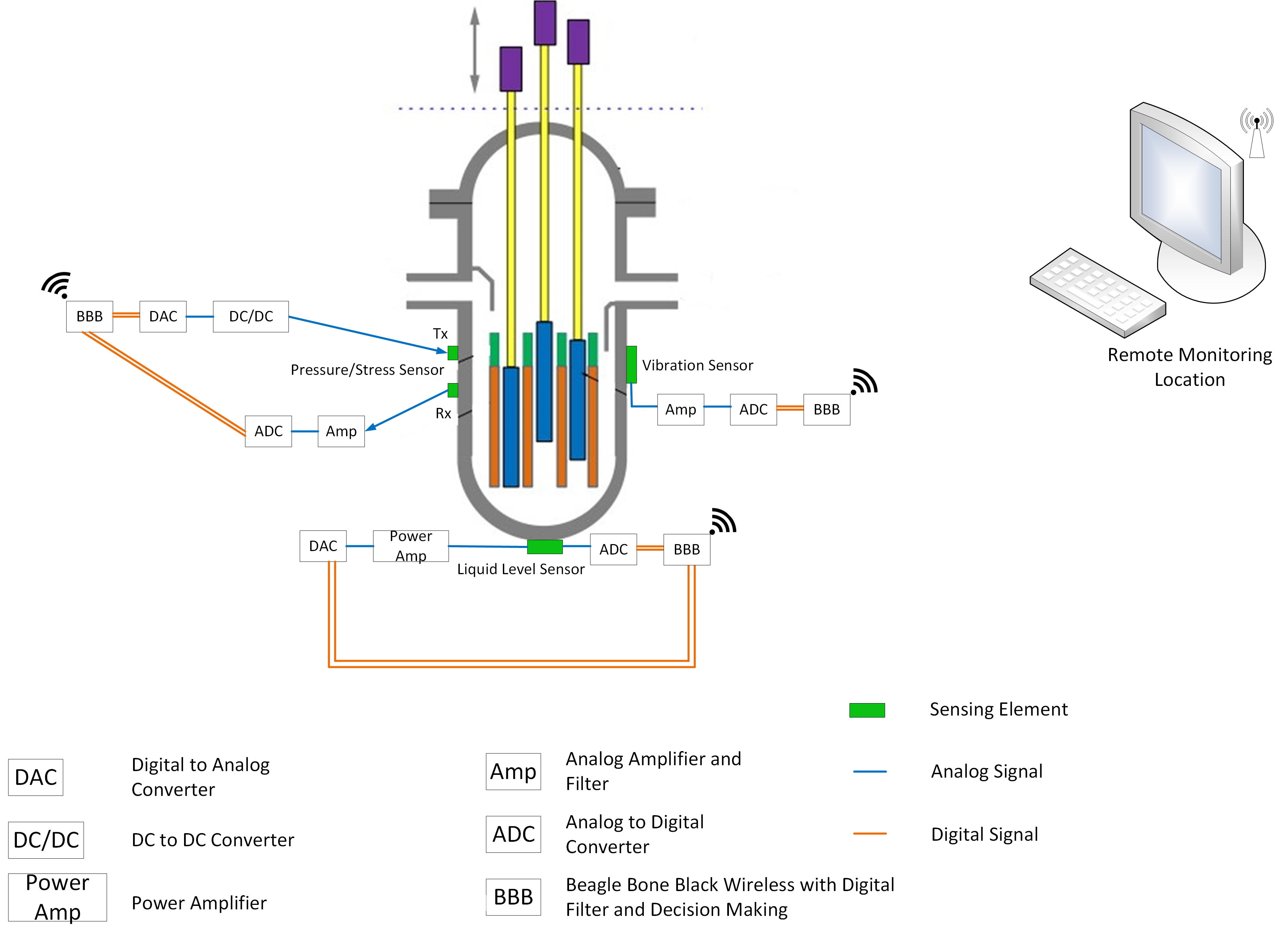

More than 10,000 sensors and detectors are usually adopted in a typical nuclear power plant (NPP) unit for measurements and controls of nuclear and non-nuclear processes, radiation monitoring, and other special applications including vibration measurements, hydrogen concentration monitoring, water conductivity and boric acid concentration measurement, or failed fuel detection, etc. (IAEA, 1999). Among a wide range of different sensing technologies, piezoelectric sensing has been increasingly used in temperature measurement, vibration monitoring, pressure and flow rate measurement, hydrogen concentration measurement, detection of water level and structural defects (Korsah, et al., 2009), largely due to the nature of compact assembly of piezoelectric devices and free from electromagnetic interference. However, harsh environments (high temperatures, high radiations, etc.) in nuclear reactors and fuel cycle systems greatly challenge the existing NPP sensing technology. Specifically, existing piezoelectric (including acoustic sensing) sensing techniques are mostly limited to applications at temperatures up to <250°C, by their lack of radiation resistance, their lack of embed-ability because of the wired electric power supply and communication, and their unknown long-term performance behavior under harsh environments.

In this project, we develop 1) high temperature (> 600°C) embedded/integrated sensors (HiTEIS) for wireless monitoring of temperature, vibration, water level, pressure and structural integrity; 2) investigate remote acoustic charging of HiTEISs using laser ultrasound; 3) implement nuclear environment compatible secured remote communication for HiTEISs; 4) verify the HiTEIS technology in reactor and fuel cycle environments.

Sponsor: