Battery Incipient Fault Digital Twin (BIF-DT)

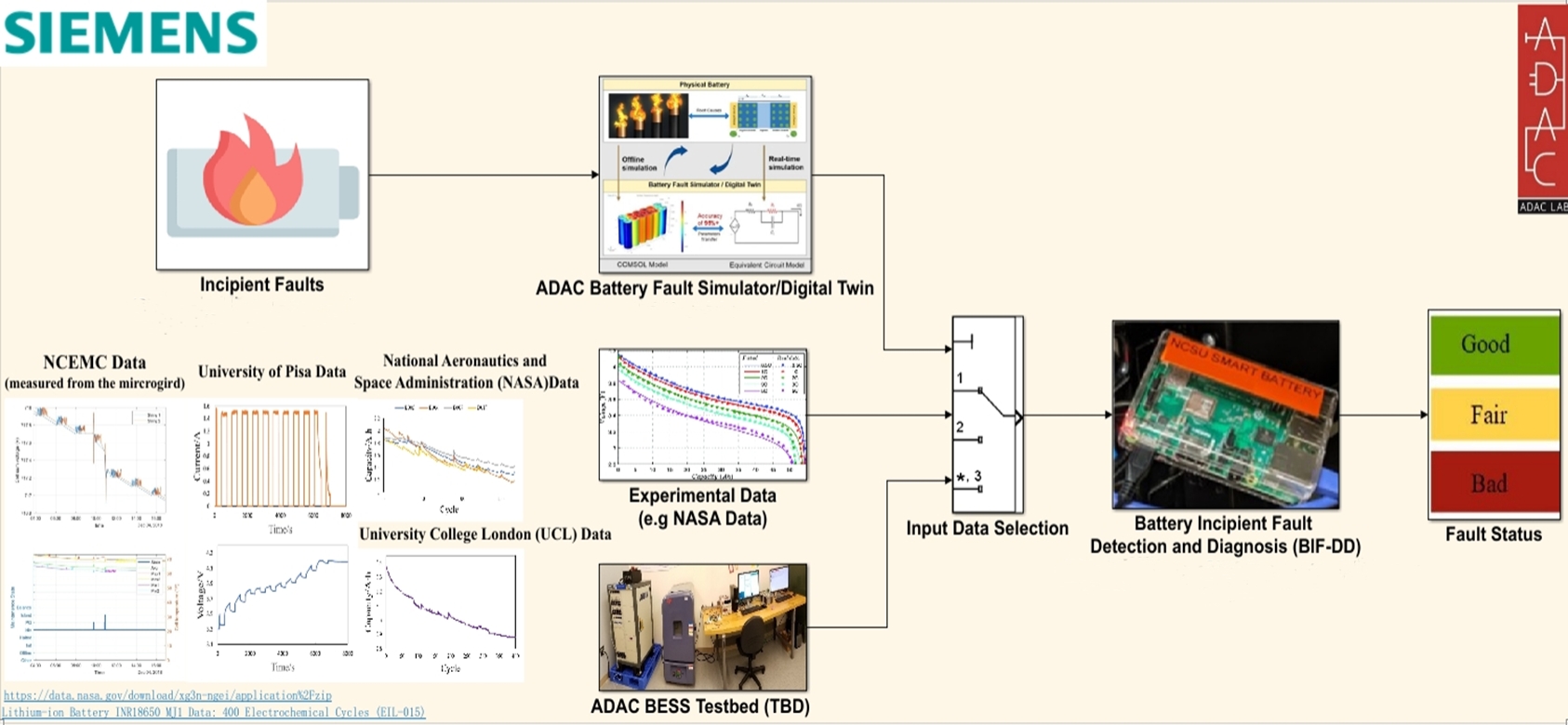

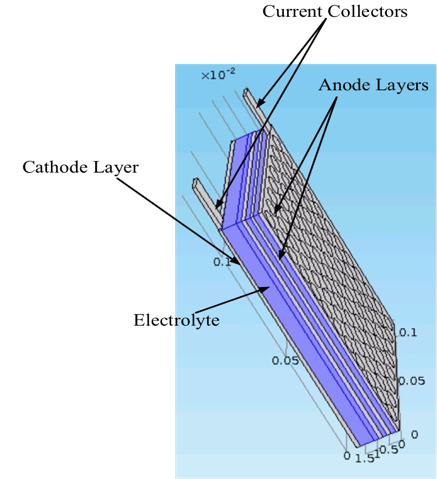

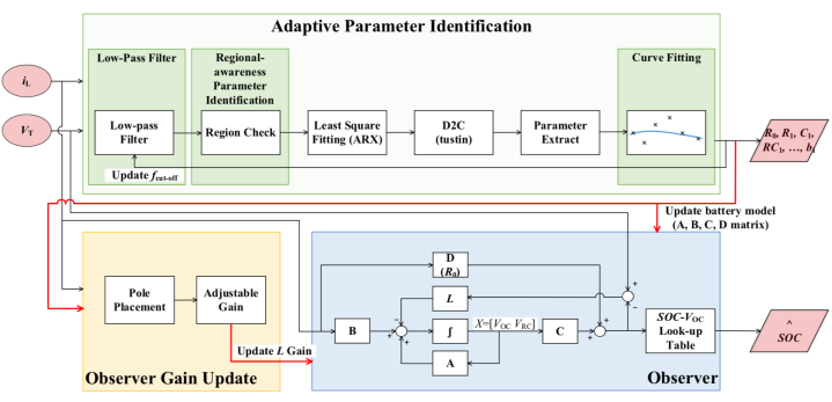

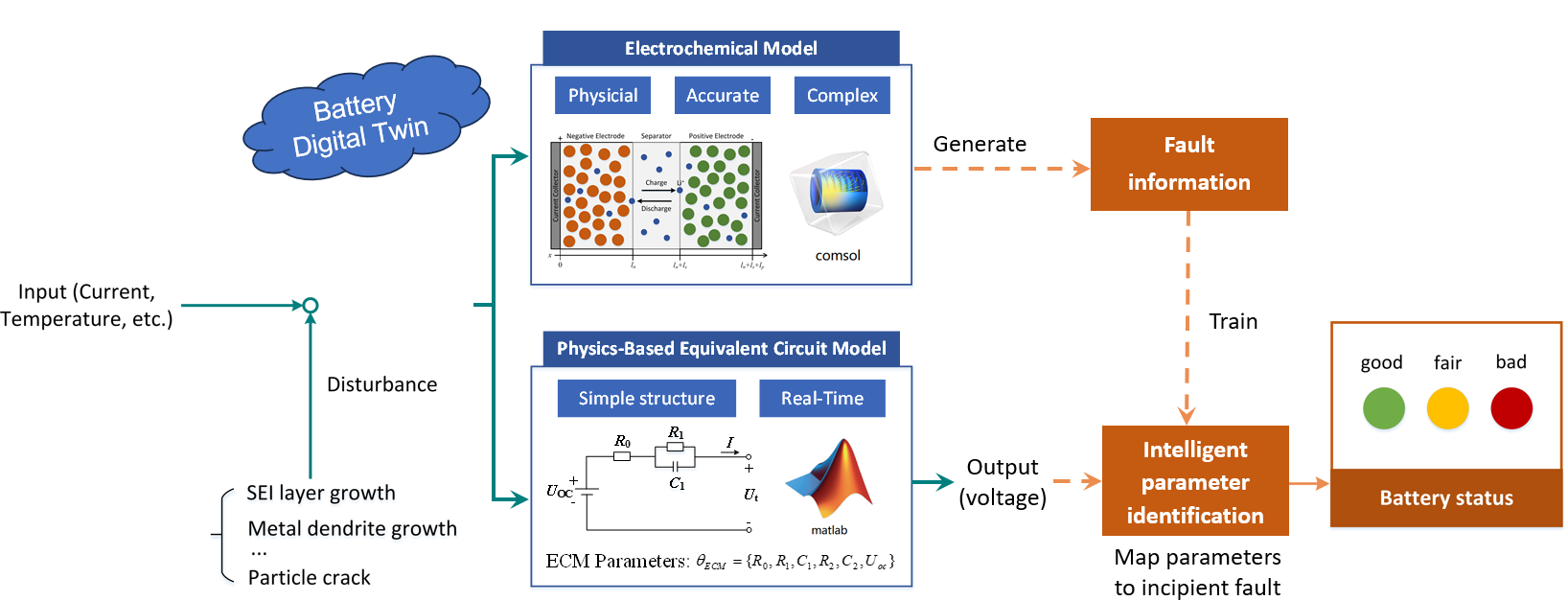

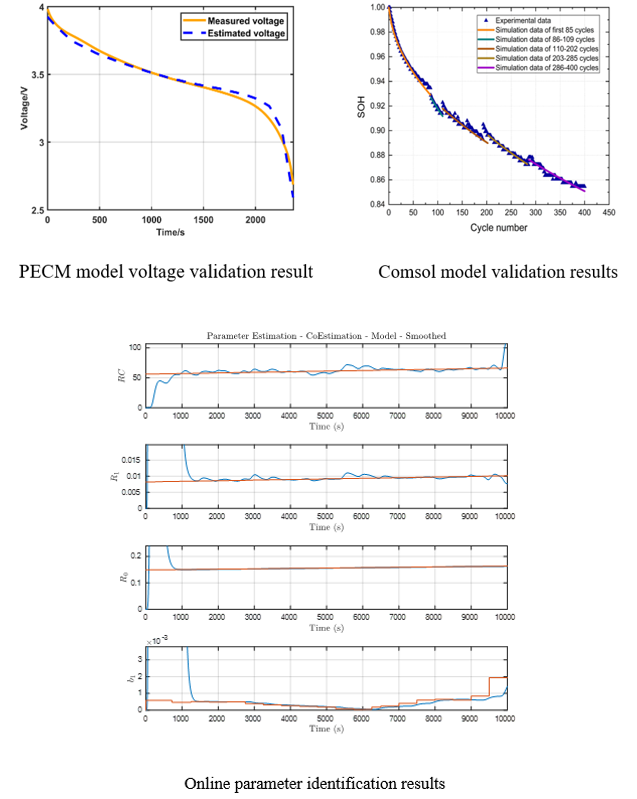

ADAC’s innovative solution addresses these safety challenges by integrating cutting-edge Battery Digital Twin technology to provide real-time fault detection and diagnosis for BESS. By combining the COMSOL Electrochemical Model with the Physics-Based Equivalent Circuit Model (PECM), our system simulates both the internal processes of the battery and its electrical behavior, ensuring accurate and fast fault tracking.

Key Features:

- Integrated Battery Digital Twin: Combines electrochemical and circuit models for real-time, comprehensive battery performance simulation.

- Fuzzy Logic Fault Detection: Uses fuzzy logic to estimate changes in battery parameters, detecting faults at their incipient stages for early intervention.

- Intelligent Parameter Identification: The system processes fault data to train an intelligent algorithm that monitors battery health in real-time. By mapping changes in battery parameters to emerging faults, the system ensures timely detection.

- Real-Time Monitoring: Continuously tracks battery conditions, such as current and temperature, providing ongoing health assessments and immediate identification of potential issues.

- Fault Simulation & Prevention: Simulates battery performance under various fault scenarios, improving detection accuracy and preventing failures.

Results:

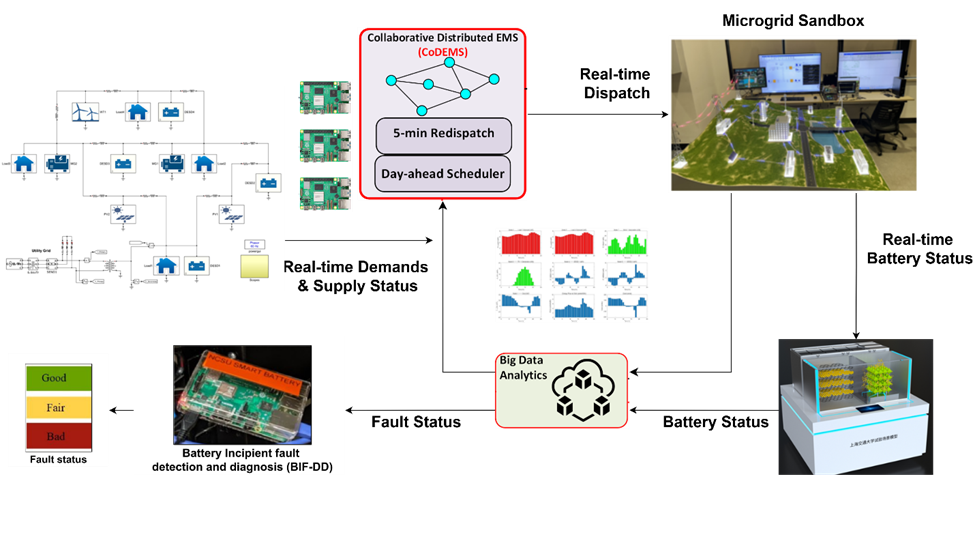

ADAC Hardware-in-Loop (HIL) Platform

To showcase our work, we have set up a Hardware-in-Loop (HIL) platform to demonstrate the integration of Energy Management Systems (EMS) and Battery Fault Simulation.

Dynamic energy management algorithms run on Raspberry Pi microcontrollers, enabling real-time microgrid scheduling visualized via a microgrid sandbox. The Battery Fault Simulator monitors battery status, while real-time demand and supply data are fed into big data analytics to predict and adjust the system’s next steps.

By combining HIL and Software-in-Loop (SIL) methods, this platform effectively demonstrates the feasibility of our research in dynamic energy management and Battery Fault Detection and Diagnosis (BIF-DD).