Advanced Interdisciplinary Energy Research Center Foundation

On the morning of November 21, the launch ceremony of the Advanced Energy Interdisciplinary Research Center (hereinafter referred to as the “Center”) of the Global College, Shanghai Jiao Tong University, was held in the Zhongji Lecture Hall of Longbin Building. Present at the event were Hesheng Wang, Dean of the Global College, Mo-Yuen Chow, Head of the Center, as well as faculty members Songliang Chen, Yuljae Cho, Yunlong Guo, Yulian He, Li Jin, Chengbin Ma, Dezhi Zhou, and others. The ceremony was hosted by faculty member Li Jin.

In his opening speech, Hesheng Wang stated that the College will establish a series of interdisciplinary research centers, and the establishment of such centers is an important strategic initiative to promote high-level scientific research development. The Center will actively foster collaboration and exchange among various research teams within the College, forming a synergistic innovation force that will provide strong support to the existing independent Principal Investigator (PI) research model. Based on the actual operation of the Center, the College will provide ample support in terms of student recruitment quotas, laboratory space, and startup funding.

Mo-Yuen Chow provided a detailed introduction to the Center’s mission, vision, and future plans. The Center will leverage the College’s dual advantages of internationalized education and interdisciplinary integration, strongly encourage academic innovation, and support the growth of young faculty and students. In the future, the Center will regularly organize academic exchange activities, gather high-level academic resources, actively promote international research collaboration and industry-academia partnerships, and strive to build an academic hub with global influence.

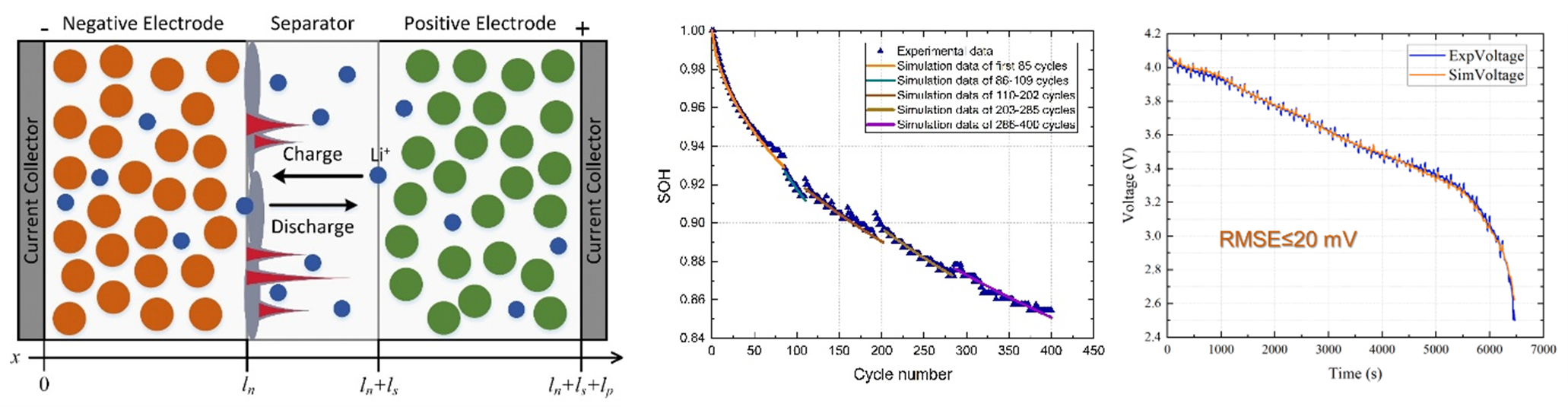

Subsequently, several faculty members and research group representatives from the College introduced the core research directions of their respective teams. The poster session was lively, with each team showcasing their latest research findings. Faculty and students engaged in enthusiastic discussions, actively exploring potential collaboration opportunities.