Lithium-ion battery performance and reliability are influenced by incipient degradation mechanisms such as SEI growth, dendrite formation, and particle cracking, which evolve gradually during operation and often precede observable failure. Modeling these early-stage faults is essential for improving battery durability and safety.

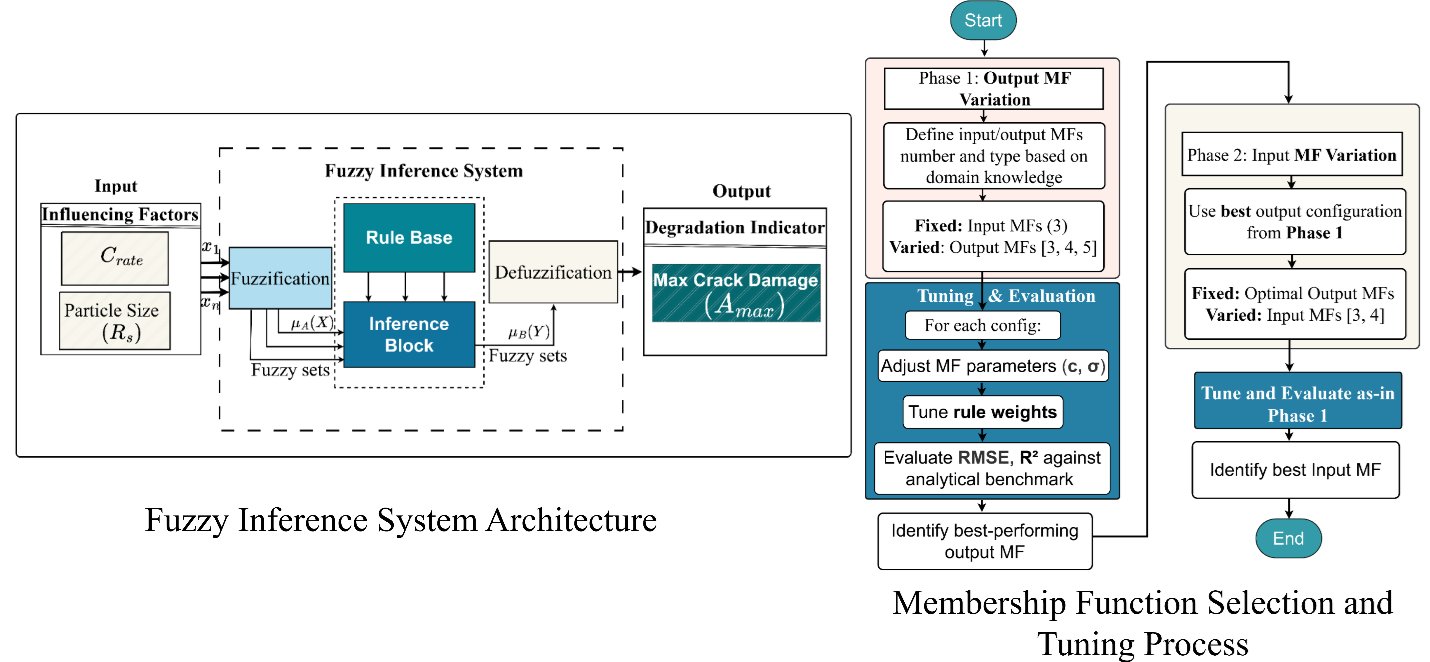

Our research develops fuzzy logic–based methodologies to model battery incipient faults in an interpretable and computationally efficient manner. Compared to data-intensive physics-based models, fuzzy systems translate qualitative degradation knowledge into transparent, rule-based surrogate models.

As a representative study, we model anode particle cracking using a fuzzy inference system, demonstrating a generalizable framework for capturing degradation trends while maintaining analytical transparency.