Digital Twin-Based Battery Incipient Fault Detection and Diagnosis3

The practical application of incipient fault detection and diagnosis in Battery Energy Storage Systems (BESS) faces significant challenges, including complex fault characteristics, limited data availability, safety concerns, and the need for scalable real-time processing. Incipient faults such as Solid Electrolyte Interface (SEI) growth and metal dendrite growth are particularly difficult to detect using conventional methods, yet they are critical to preventing catastrophic battery failures. These challenges highlight the urgent need for advanced, reliable diagnostic tools that can operate accurately under real-world conditions, ensuring both the safety and longevity of BESS installations.

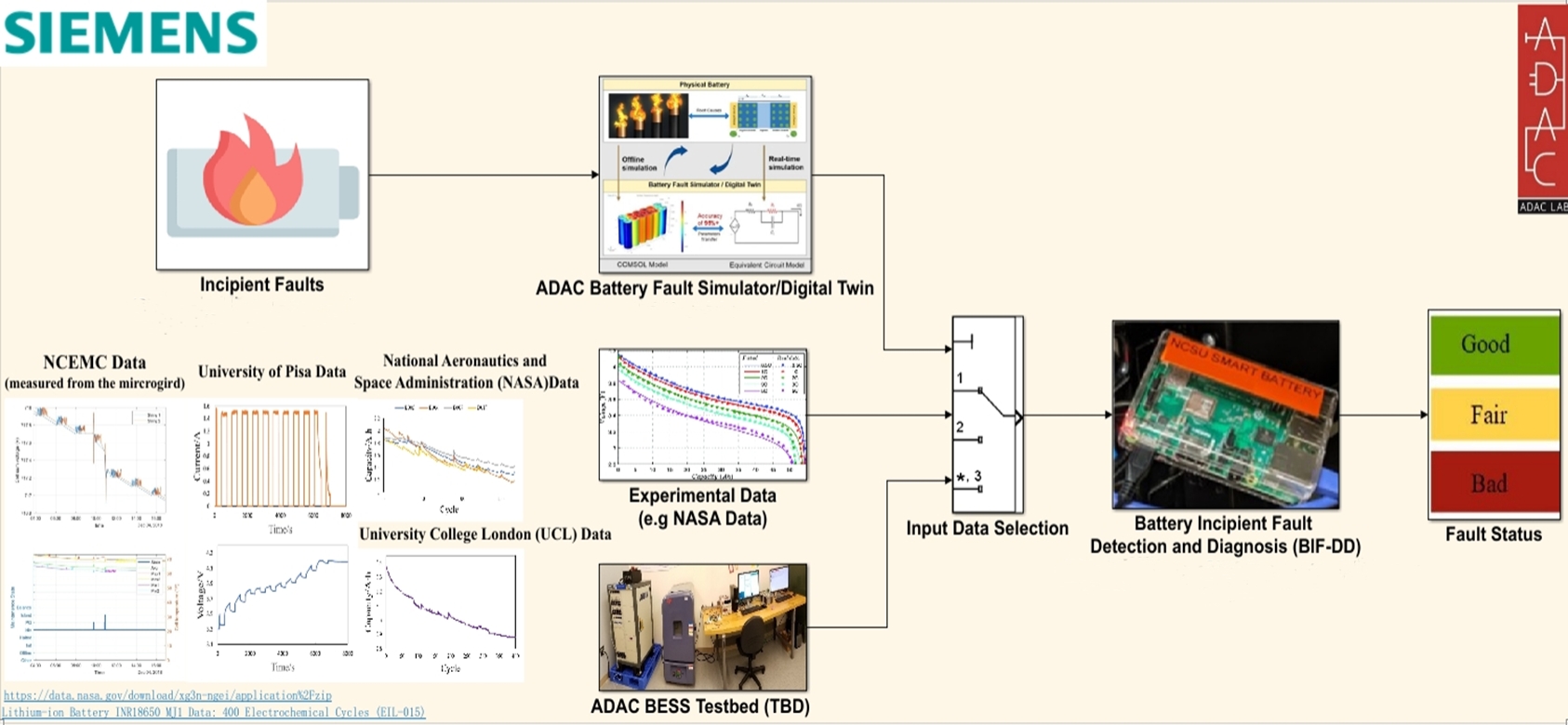

In response to these challenges, we have been develping the Battery Incipient Fault Digital Twin (BIF-DT), an advanced integrated framework designed to simulate and detect early-stage battery degradation. The BIF-DT platform uniquely combines an electrochemical model with a physics-based circuit model, enabling a comprehensive and multi-faceted approach to fault diagnosis. This dual-model structure allows for high-fidelity simulation of internal battery processes while maintaining computational efficiency suitable for practical applications. To date, development of the BIF-DT has progressed significantly, with both constituent models successfully validated using publicly available datasets, demonstrating remarkable accuracy in detecting incipient faults. This progress has been documented through multiple publications, establishing a solid foundation of scientific credibility for the platform. In the IEEE IESES 2025 tutorial, our self-developed BIF-DT is also presented to the audience.

Looking forward, the BIF-DT platform holds considerable promise for enhancing the reliability and safety of battery energy storage systems across various applications. The validated accuracy of our models provides a strong basis for transitioning this technology from research to real-world implementation. Future work will focus on refining the platform’s scalability and real-time processing capabilities, ultimately aiming to deploy the BIF-DT as a proactive diagnostic tool that can predict and prevent battery failures in commercial and grid-scale energy storage systems, thereby contributing to more secure and efficient renewable energy integration.

Publications:

[1] Ziqi Wang and Mo-Yuen Chow, “Battery Modeling of SEI and Metal Dendrite Growth: A Transmission Line Circuit Framework with Genetic Algorithm-Identified Parameters ,” 2025 IEEE 20th Conference on Industrial Electronics and Applications (ICIEA), Yantai, China, 2025, pp. 1-6, doi: 10.1109/ICIEA65512.2025.11149030.

[2] Junya Shao, Mo-Yuen Chow, Zhiping Tan and Huiqin Jin, “Solid Electrolyte Interface Growth Fault Modeling for Battery State of Health Simulation,” 2025 IEEE International Conference on Industrial Technology (ICIT), Wuhan, China, 2025, pp. 1-6, doi: 10.1109/ICIT63637.2025.10965289.

[3] Ziqi Wang, Mo-Yuen Chow, Zhiping Tan and Huiqin Jin, “Modelling of the Solid Electrolyte Interface Growth Using Physics-Based Equivalent Circuit Model,” 2025 IEEE International Conference on Industrial Technology (ICIT), Wuhan, China, 2025, pp. 1-6, doi: 10.1109/ICIT63637.2025.10965250.

Sponsor: